Our main priority is to ensure the availability of life-saving drugs for the citizens of Kazakhstan and Central Asia. Polpharma Santo plant has advanced technologies, high-tech equipment and qualified specialists producing drugs in accordance with international quality standards. This is our contribution to the care of public health and national security.Adam Aleksiejuk

Polpharma Santo CEO

1

billion

tablets

255

million

capsules

7,5

million

sachets

135

tons

of tablet mass by wet granulation

46.7

million

vials with cephalosporin antibiotics

15.5

million

vials with penem/mycin antibiotics

8.4

tons

of million vials with non-sterile liquid dosage forms.

250

million

injection ampoules

1882

Plant establishment

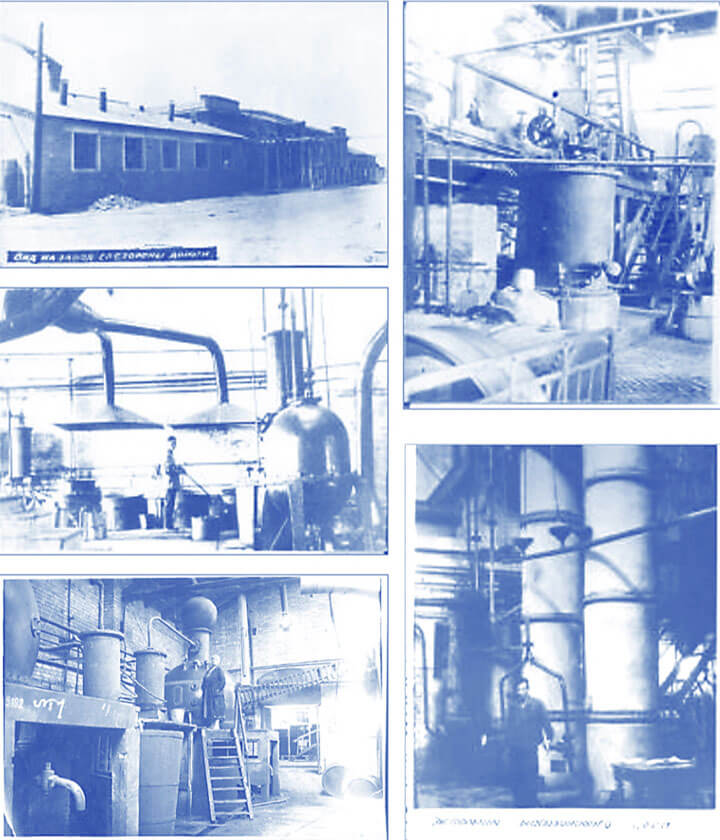

The SANTO plant is one of the oldest pharmaceutical

enterprises in Kazakhstan. It was founded in 1882 by

merchants Ivanov and Savenkov as a plant for the production

of the Santonin drug - an anthelmintic agent based on

wormwood (Artemisia cina). Today, a sprig of wormwood adorns

the coat of arms of Shymkent, for which the opening of a

pharmaceutical enterprise was a powerful impetus for

development.

1917-1991

Working in the USSR period

During the Soviet period, the plant was the largest producer

of pharmaceutical substances from raw plant materials and a

manufacturer of narcotic agents.

1993

Reorganization into Chimpharm JSC

Commencement of the pharmaceutical production large-scale

modernization in accordance with the international GMP

quality standard within the framework of the implementation

of an investment project worth about 108 million US dollars.

2011

Merger into Polpharma Group

Commencement of the pharmaceutical production large-scale

modernization in accordance with the international GMP

quality standard within the framework of the implementation

of an investment project worth about 108 million US dollars.

2014

Launching production of medicines in ampoules and

infusions

A new production workshop was opened within the framework of

the FIID State Program. At the moment, parenteral solutions

of large and small dosages are produced in this workshop.

2016

Launching production of antibiotic powders (GMP)

A new workshop for the production of antibiotic powders

(cephalosporins and penems/mycins) complies with the

international GMP standard. The production is arranged on

two separate lines.

2017

Launching production of oral solid dosage forms (GMP)

A new workshop for the production of oral solid dosage forms

by dry granulation method was launched as part of the

plant’s 135th anniversary celebration.

2018

Commencement of production of oral liquid dosage forms

(GMP) as well as modernization of the warehouse (GDP)

As part of the product range expansion, a new manufacturing

field was introduced - the production of oral liquid dosage

forms. GMP recertification was successfully passed, and a

GDP compliance certificate was obtained for the modernized

pharmacy warehouse of the plant.

2019

Commencement of production of oral solid dosage forms by wet

granulation method (GMP); the opening of the Digital

Engineering and Education Center as well as a sculpture

named “Looking into the Future” at the SANTO plant.

2020

Winning in the BEST RX CORPORATION OF KAZAKHSTAN 2020

nomination

For the first time, SANTO became a winner of IQVIA RX &

CONSUMER HEALTH AWARDS 2020 in the pharmaceutical market of

Kazakhstan in the BEST RX CORPORATION KAZAKHSTAN 2020

nomination.

2021

Winning the PARYZ Republican Contest

For the first time, SANTO became a winner of the Paryz-2021

Republican Contest on Social Responsibility in the

nomination “The Best Socially Responsible Enterprise”.

2021

Winning the EURASIAN PHARMA AWARD Contest

For the first time, SANTO became the winner of the Eurasian

Pharma Award-2021 Contest in the nomination “Local Company

of the Year”.

2022

Market leader

SANTO became the market leader according to the results of a study by the independent consulting company Vi ortis

2023

Launch of new sites in the workshop of CTPLS No. 3

Opening of a solid medicine production site using compaction technology (dry granulation) and a new tablet coating site in the PPSM plant No. 3

2023

Victory at the Eurasian Pharma Awards

The winner in the Eurasian Pharma Awards in the nominations "Local Company of the Year" and "Exporter of the Year"

2023

Request to the EU in order to obtain a GMP certificate

SANTO sent a request to the European Union to inspect the plant in Kazakhstan in order to obtain a GMP certificate of the European standard

Financial statement audit services

To ensure the reliability of its financial statements, JSC "CHIMPHARM" engages an independent auditing organization.

Current Auditor:

LLP "Ernst & Young," 050060, Almaty, Al-Farabi Ave. 77/7, "Esentai Tower" building, Tel: +7 (7272) 585960.

НBased on the Resolution of the Shareholder owning all voting shares of JSC "CHIMPHARM" dated February 2024, JSC "CHIMPHARM" entered into a contract for the provision of financial statement audit services for 2023 with LLP "Ernst & Young."

Audit Service Fee for the financial statement audit services:

Under the above-mentioned agreement, the fee payable to the auditing organization for 2023 is KZT 33,500,000, excluding VAT and overhead costs.

List of financial statement audit and related services provided by the external auditor for 2023, according to the aforementioned agreement:

- Conducting an audit of the Company's financial statements for the purpose of the Group's consolidated financial statements for the period from January 1 to December 31, 2023, with the preparation of an internal Group report in accordance with the instructions of the external auditor of JSC "CHIMPHARM."

- Conducting an audit of the Company's financial statements prepared in accordance with IFRS for the period from January 1 to December 31, 2023;

- "Related Services" – auxiliary services performed by the Auditor that are necessary for the proper and high-quality provision of services and fulfillment of contractual obligations as stipulated in the agreements.